Due to the steel pipe transporting gas or liquid need to bear a certain pressure, internal stress produced in the cold rolling process must be eliminated. Welding process, because local overheating will cause the pipe deformation and shrinkage stress, so steel pipe return to heat treatment after welding to eliminate internal stress.

Due to the steel pipe transporting gas or liquid need to bear a certain pressure, internal stress produced in the cold rolling process must be eliminated. Welding process, because local overheating will cause the pipe deformation and shrinkage stress, so steel pipe return to heat treatment after welding to eliminate internal stress.

PWHT is based on the hardness of the steel, the thickness of the welding parts, structural rigidity, welding methods and conditions of use. General carbon steel welding performance is good, the welding can be without preheated and heat treatment. But for the high carbon content and high stiffness of the welding parts, it is required to preheat and heat treatment, such as the wall thickness of 30mm carbon steel pipe.

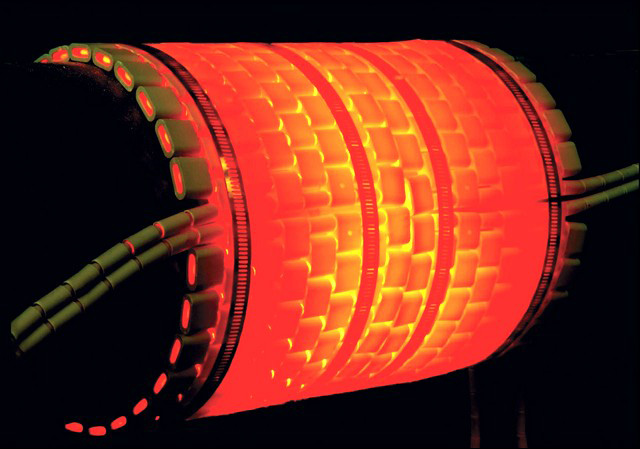

The method of PWHT is electric heating. The caterpillar electric heater and linear electric heater should be fixed on the parts which are needed to PWHT; they connect with the automatic controller through cable. And the thermocouple should be fixed on the parts needed to PWHT through the compensating conductor. It connects with the computer automatic controller. Then the controller will work automatically according to the process parameter that is being inputted into the controller.

| Steel Grade | Preheat Before Welding | Post Weld Heat Treatment | ||

|---|---|---|---|---|

|

Wall Thickness (mm) |

Temperature (℃) |

Wall Thickness (mm) |

Temperature (℃) |

|

| C | ≥26 | 100~200 | >30 | 600~650 |

| C-Mn | ≥15 | 150~200 | >20 | |

| Mn-V | 560~590 | |||

| C-0.5Mo | 600~650 | |||

| 0.5Cr-0.5Mo | 650~700 | |||

| 1Cr-0.5Mo | ≥10 | 150~250 | >10 | |

| 1Cr-0.5Mo-V | ≥6 | 200~300 | >6 | 700~750 |

| 1.5Cr-1Mo-V | ||||

| 2.25Cr-1Mo | ||||

| 5Cr-1Mo | 250~350 | |||

| 9Cr-1Mo | 750~780 | |||

| 2Cr-0.5Mo-WV | ||||

| 3Cr-1Mo-VTi | ||||

| 12Cr-1Mo-V | ||||

Pipe assembly which should be post weld head treatment treated in the heat treatment furnace as far as possible, but the component should not be welded with the valve and other components.

When the welded pipeline components cannot add heat treatment furnace, heat treatment allows segmentation. In the subsection heat treatment, the length of the repeated heating is at least 300mm, at the same time, it is necessary to protect the outer part of the furnace, in order to prevent harmful temperature gradient.

When local heat treatment is applied weld joints, a circumferential band of the run pipe, and of the branch where applicable, shall be heated until the specified temperature range exists over the entire pipe section, gradually diminishing beyond a band which includes the weldment or the bent or formed section and at least 25mm beyond the ends thereof.