In the processing of oil pipeline, used steel pass through a series of processes before leaving factory. If the performance and use of steel are different, the final delivery status is also different. There are several common delivery conditions: hot rolling treatment, cold stretching treatment, normalizing treatment, annealing state, high tempering state and solid treatment.

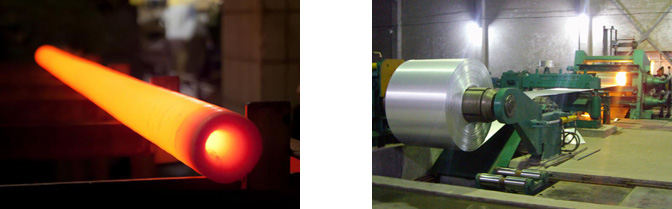

After hot rolling or casting, the steel is no longer specialized for heat treatment and deliver directly after cooling, that is called hot rolling treatment. The terminal temperature of hot rolled is generally 800 to 900 degrees Celsius. After that, steel is generally cooling in the air, thus the state is equivalent to normalizing treatment. Due to the terminal temperature is high or low, different from normalizing heating temperature controlled strictly, The fluctuation of steel with hot rolling is greater than normalizing treatment on structure and properties.

The surface of steel with hot rolling is covered with a layer of iron oxide, which has a certain corrosion resistance. Therefore, requirements of storage and transportation is less strict than that of cold stretching and large and medium steel plate can be stored in the open yard.

The steel, which is through cold stretching, without any heat treatment and direct delivery, is known as cold stretching. Compared with the state of hot rolled, cold stretching steel has high precision, good surface quality and higher mechanical properties. Due to the surface of steel with cold stretching is without oxide layer covered, and there are a lot of internal stress, it is extremely easy to suffer corrosion or rust. As a result, the packaging and storage of steel with cold stretching have strict requirements. It’s generally to be kept in the warehouse and the warehouse temperature and humidity should be pay attention.

Through normalizing treatment before leave factory, the state of steel is called normalized condition. Because the terminal temperature of normalizing heating is strictly controlled, the performance and organization of steel is more uniform. Compared with annealing state, due to the quicker of cooling rate, the more of pearlite number and grain refinement of steel, the normalizing treatment steel has high mechanical properties. Carbon steel and alloy steel is generally using normalizing treatment.

Through normalizing treatment before leave factory, the state of steel is called normalized condition. Because the terminal temperature of normalizing heating is strictly controlled, the performance and organization of steel is more uniform. Compared with annealing state, due to the quicker of cooling rate, the more of pearlite number and grain refinement of steel, the normalizing treatment steel has high mechanical properties. Carbon steel and alloy steel is generally using normalizing treatment.

Through high tempering heating treatment before leave factory, the state of steel is known as high tempering state. High tempering has high tempering temperature and it is conducive to the thorough eliminate internal stress. Carbon structure and alloy steel can be used in high tempering state delivery. Some high strength stainless steel, due to the strengthening of the alloying elements, often conduct a high tempering after quenching to assemble carbide in steel so that obtain the organization of tempered sorbite. As a result, the delivery condition of the steel has a good cutting performance.

Before leave factory, steel is called annealing state through annealing treatment. The purpose of annealing is mainly eliminate and improve the tissue defects and internal stress in the former process, and make preparation for the organization and performance of the following process. Alloy steel, cold heading steel, bearing steel, tool steel, turbine blade steel are commonly used in annealing state delivery.

Before leave factory, steel is called annealing state through annealing treatment. The purpose of annealing is mainly eliminate and improve the tissue defects and internal stress in the former process, and make preparation for the organization and performance of the following process. Alloy steel, cold heading steel, bearing steel, tool steel, turbine blade steel are commonly used in annealing state delivery.

The delivery condition of the solid treatment before leaving the factory is referred to solid treatment state. This state is mainly used on Austenite stainless steel material factory processing. Through solid treatment to improve the toughness and plasticity of steel and create the conditions for further cold processing, it can also be prepared for further precipitation hardening.