What is coiled tubing?

What is coiled tubing

In oil and gas industry, coiled tubing, also called flexible tubing or CT, is a long continuous string of tubing spooled on a large reel. It is normally made from low carbon alloy steel and ranges in diameter from 8 feet to 12 feet. Coiled tubing can be straightened prior to being inserted into the wellbore and recoiled to spool back on the reel later.

Coiled tubing was first originated from submarine pipeline produced in the World War II in order to transport fuel from England to European Continent to assist the Allied armies, which was a plan called “PLUTO”, an acronym for “Pipe Lines under the Ocean”. Since the 1960s, coiled tubing has been actually used in oil and gas industries. The development of science and technology spurred the rise and improvement of coiled

tubing technology. During 1980s, it began to be widely applied in drilling, workover, completion, etc, playing am indispensible role in oil and gas industry. It is clear that CT technology will continue to bring more applications in oil market.

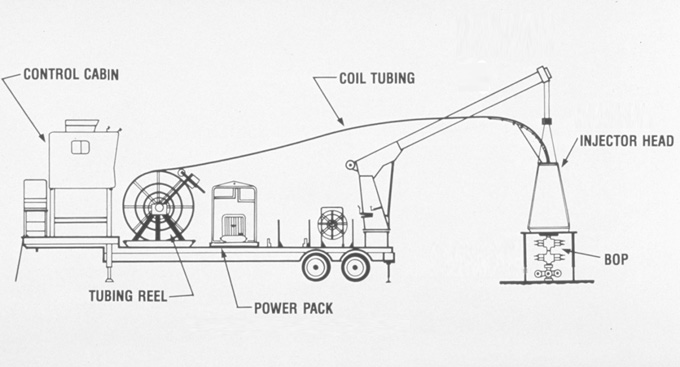

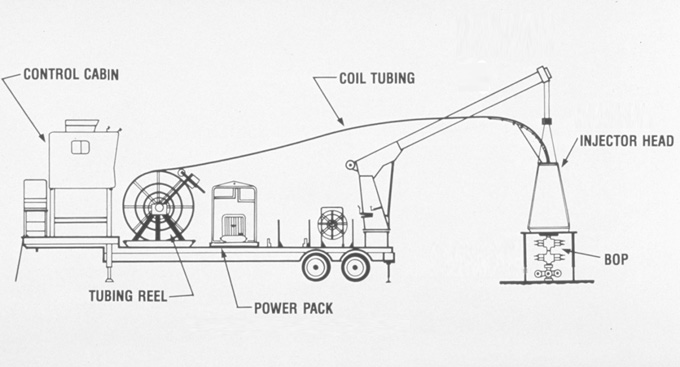

Coiled Tubing Unit

The Coiled tubing unit mainly consists of five parts, the injector head, coiled tubing reel, control cabin, power pack and well control equipment.

-

The injector head is one of the most important components of the coiled tubing units. It is used to provide the driving force to push and pull the coil in and out of the well bore during operations.

-

The coiled tubing reel is mainly used to store and transport the CT during well intervention and drilling application.

-

The control cabin refers to a place the operators monitor and manipulate the coiled tubing to ensure the proper function of the CT

-

Power pack is a device used to offer the hydraulic power needed for the CT operation.

Besides the above components, well control equipment is also an inevitable part of the coiled tubing unit. It is composed of two elements, BOP and blowout preventer. There is a sealing device in the blowout preventer to isolate the pressure in the wells. The BOP is located beneath the blowout preventer, used to control the pressure in the wells. It is specially designed for coiled tubing operation, with pairs of rams in it to offer the various functions.

Coiled Tubing Benefits

The reason why CT is enjoying more popularity both home and abroad is that it has the following benefits:

-

Safe and high operating efficiency

-

Fewer personnel needed at the site

-

Easy to operate and save cost

-

Smaller environmental footprint

-

Constantly pumping fluids through when running and retrieving the coil

Coiled Tubing Application

Due to the above benefits of coiled tubing, it is widely used in various areas. One of the most important applications of CT is the cleanout and removal of filler materials that impede fluid smooth flow and affect well productivity. Filler materials are normally sand or materials produced from the surface, fragment from the workover. The main removal process involves circulating a cleanout fluid through a jet nozzle fixed at the end of the CT. The filler material are taken to the surface and carried out of the wellbore by the annulus between the coiled tubing.

Coiled tubing can be also utilized in well completion program, in which it is used to transport and installation of the completion equipment. As the CT string is continuous, operators can carry out the completion program without having to consider the problems related to connections.

Coiled tubing drilling technique has gained more fame in oil and gas industries in recent years. Coiled tubing drilling are normally used in two categories—directional and non-directional wells. Non-directional wells use a traditional drilling assembly to connect a downhole motor. Directional wells use an orienting equipment to control the direction of the well.

Conclusion

As a time-and-cost-effective facility, coiled tubing can fully satisfy your demands in a number of aspects. There is still room for CT to improve itself. Great revolutions will sure to occur in CT technology. The enhancement of coiled tubing will enable more applications in oil and gas industry.