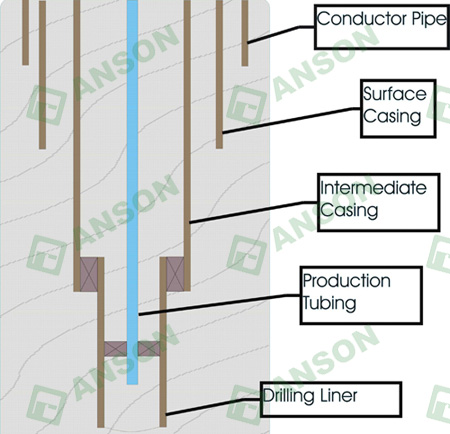

Anson also have much experience on supply casing pipes, which will be best rate and international certificated quality. Casing is large diameter pipe that is assembled and inserted into a recently drilled section of a borehole and typically held into place with cement.

With the casing set depths determined, hole sizes and casing sizes must follow. The hole drilled for each casing string must be large enough to easily fit the oil well casing inside it, allowing room for cement between the outside of the casing and the hole.

Casing design for each size is done by calculating the worst conditions that may be faced during drilling and production. Mechanical properties of designed pipes such as collapse resistance, burst pressure, and axial tensile strength must be sufficient for the worst conditions.

In the planning stages of a well a drilling engineer, usually with input from geologists and others, will pick strategic depths at which the hole will need to be cased in order for drilling to reach the desired total depth. This decision is often based on subsurface data such as formation pressures, strengths, and makeup, and is balanced against the cost objectives and desired drilling strategy.

|

|

|

|

Dimension range(OD inch):4 1/2”---30”

Dimension range(OD mm):114.3---762

Standard: API SPEC 5CT

Main Steel Grade: H40, J55, K55, N80, N80Q, L80, T95, P110 etc

Type of Casing:Plain, BTC, STC, LTC, Other Premium Thread.

| Standard | Grade | Tensile Strength(MPa) | Yield Strength(MPa) | Elongation(%) | Hardness |

|---|---|---|---|---|---|

| API SPEC 5CT | J55 | ≥517 | 379~552 | 0.5% | ≤241HB |

| K55 | ≥655 | 379~552 | 0.5% | ||

| N80 | ≥689 | 552~758 | 0.5% | ||

| L80(13Cr) | ≥655 | 552~655 | 0.5% | ||

| P110 | ≥862 | 758~965 | 0.6% |

| Standard | Grade | Composition(%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V | AIs | ||

|

API SPEC 5CT |

J55K55 | 0.34~0.39 |

0.20~ 0.35 |

1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | ≤0.020 | ||

| (37Mn5) | ||||||||||||

| N80 | 0.34~0.38 |

0.20~ 0.35 |

1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 |

0.11 ~0.16 |

≤0.020 | ||||

| (36 Mn2V) | ||||||||||||

| L80(13Cr) | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 |

12.0~ 14.0 |

≤0.20 | ≤0.20 | ≤0.020 | |||

| P110 | 0.26~0.35 |

0.17~ 0.37 |

0.40~0.70 | ≤0.020 | ≤0.010 |

0.80~ 1.10 |

≤0.20 | ≤0.20 |

0.15 ~0.25 |

≤0.08 | ≤0.020 | |

| (30CrMo) | ||||||||||||

| Labels |

Outside diameter |

T&C |

Wall thickness |

Type of end-finish | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | J55/K55 | M65 | L80/R95 | N80-1/Q | C90/T95 | P110 | Q125 | |||

| 4-1/2 | 9.50 | 114.30 | 14.14 | 5.21 | PS | PS | - | - | - | - | - |

| 10.50 | 114.30 | 15.63 | 5.69 | PSB | PSB | - | - | - | - | - | |

| 11.60 | 114.30 | 17.26 | 6.35 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 13.50 | 114.30 | 20.09 | 7.37 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 15.10 | 114.30 | 22.47 | 8.56 | - | - | - | - | - | PLB | PLB | |

| 5 | 11.50 | 127.00 | 17.11 | 5.59 | PS | PS | - | - | - | - | - |

| 13.00 | 127.00 | 19.35 | 6.43 | PSLB | PSLB | - | - | - | - | - | |

| 15.00 | 127.00 | 22.32 | 7.52 | PSLB | PLB | SLB | PLB | PLB | PLB | ||

| 18.00 | 127.00 | 26.79 | 9.19 | - | PLB | SLB | PLB | PLB | PLB | PLB | |

| 21.40 | 127.00 | 31.85 | 11.10 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 23.20 | 127.00 | 34.53 | 12.14 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 24.10 | 127.00 | 35.87 | 12.70 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 5-1/2 | 14.00 | 139.70 | 20.83 | 6.20 | PS | PS | - | - | - | - | - |

| 15.50 | 139.70 | 23.07 | 6.98 | PSLB | PSLB | - | - | - | - | - | |

| 17.00 | 139.70 | 25.30 | 7.72 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 20.00 | 139.70 | 29.76 | 9.17 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 23.00 | 139.70 | 34.23 | 10.54 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 26.80 | 139.70 | 39.88 | 12.70 | - | - | - | - | P | - | - | |

| 29.70 | 139.70 | 44.20 | 14.27 | - | - | - | - | P | - | - | |

| 32.60 | 139.70 | 48.52 | 15.88 | - | - | - | - | P | - | - | |

| 35.30 | 139.70 | 52.53 | 17.45 | - | - | - | - | P | - | - | |

| 38.00 | 139.70 | 56.55 | 19.05 | - | - | - | - | P | - | - | |

| 40.50 | 139.70 | 60.27 | 20.62 | - | - | - | - | P | - | - | |

| 43.10 | 139.70 | 64.14 | 22.22 | - | - | - | - | P | - | - | |

| 6-5/8 | 20.00 | 168.28 | 29.76 | 7.32 | PSLB | PSLB | - | - | - | - | - |

| 24.00 | 168.28 | 35.72 | 8.94 | PSLB | PLB | PLB | PLB | PLB | PLB | - | |

| 28.00 | 168.28 | 41.67 | 10.59 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 32.00 | 168.28 | 47.62 | 12.06 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 7 | 17.00 | 177.80 | 25.30 | 5.87 | - | - | - | - | - | - | - |

| 20.00 | 177.80 | 29.76 | 6.91 | PS | PS | - | - | - | - | - | |

| 23.00 | 177.80 | 34.23 | 8.05 | PSLB | PLB | PLB | PLB | PLB | - | - | |

| 26.00 | 177.80 | 38.69 | 9.19 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 29.00 | 177.80 | 43.16 | 10.36 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 32.00 | 177.80 | 47.62 | 11.51 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 35.00 | 177.80 | 52.09 | 12.65 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 38.00 | 177.80 | 56.55 | 13.72 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 42.70 | 177.80 | 63.55 | 15.88 | - | - | - | - | P | - | - | |

| 46.40 | 177.80 | 69.05 | 17.45 | - | - | - | - | P | - | - | |

| 50.10 | 177.80 | 74.56 | 19.05 | - | - | - | - | P | - | - | |

| 53.60 | 177.80 | 79.77 | 20.62 | - | - | - | - | P | - | - | |

| 57.10 | 177.80 | 84.98 | 22.22 | - | - | - | - | P | - | - | |

| 7-5/8 | 24.00 | 193.68 | 35.72 | 7.62 | - | - | - | - | - | - | |

| 26.40 | 193.68 | 39.29 | 8.33 | PSLB | PSLB | PLB | PLB | PLB | - | - | |

| 29.70 | 193.68 | 44.20 | 9.52 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 33.70 | 193.68 | 50.15 | 10.92 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 39.00 | 193.68 | 58.04 | 12.70 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 42.80 | 193.68 | 63.69 | 14.27 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 45.30 | 193.68 | 67.42 | 15.11 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 47.10 | 193.68 | 70.09 | 15.88 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 51.20 | 193.68 | 76.20 | 17.45 | - | - | - | - | P | - | - | |

| 55.30 | 193.68 | 82.30 | 19.05 | - | - | - | - | P | - | - | |

| 7-3/4 | 46.10 | 196.85 | 68.61 | 15.11 | - | - | P | P | P | P | P |

| 8-5/8 | 24.00 | 219.08 | 35.72 | 6.71 | PS | PS | - | - | - | - | - |

| 28.00 | 219.08 | 41.67 | 7.72 | PS | - | - | - | - | - | ||

| 32.00 | 219.08 | 47.62 | 8.94 | PSLB | PSLB | - | - | - | - | - | |

| 36.00 | 219.08 | 53.58 | 10.16 | PSLB | PSLB | PLB | PLB | PLB | PLB | - | |

| 40.00 | 219.08 | 59.53 | 11.43 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 44.00 | 219.08 | 65.48 | 12.70 | - | - | PLB | PLB | PLB | PLB | - | |

| 49.00 | 219.08 | 72.92 | 14.15 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 9-5/8 | 32.30 | 244.48 | 48.07 | 7.92 | - | - | - | - | - | - | - |

| 36.00 | 244.48 | 53.58 | 8.94 | PSLB | PSLB | - | - | - | - | - | |

| 40.00 | 244.48 | 59.53 | 10.03 | PSLB | PSLB | PLB | PLB | PLB | - | - | |

| 43.50 | 244.48 | 64.74 | 11.05 | - | PLB | PLB | PLB | PLB | PLB | - | |

| 47.00 | 244.48 | 69.95 | 11.99 | - | PLB | PLB | PLB | PLB | PLB | PLB | |

| 53.50 | 244.48 | 79.62 | 13.84 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 58.40 | 244.48 | 86.91 | 15.11 | - | - | PLB | PLB | PLB | PLB | PLB | |

| 59.40 | 244.48 | 88.40 | 15.47 | - | - | - | - | P | - | - | |

| 64.90 | 244.48 | 96.58 | 17.07 | - | - | - | - | P | - | - | |

| 70.30 | 244.48 | 104.62 | 18.64 | - | - | - | - | P | - | - | |

| 75.60 | 244.48 | 112.51 | 20.24 | - | - | - | - | P | - | - | |

| 10-3/4 | 32.75 | 273.05 | 48.74 | 7.09 | - | - | - | - | - | - | - |

| 40.50 | 273.05 | 60.27 | 8.89 | PSB | PSB | - | - | - | - | - | |

| 45.50 | 273.05 | 67.71 | 10.16 | PSB | PSB | - | - | - | - | - | |

| 51.00 | 273.05 | 75.90 | 11.43 | PSB | PSB | PSB | PSB | PSB | PSB | - | |

| 55.50 | 273.05 | 82.60 | 12.57 | - | PSB | PSB | PSB | PSB | PSB | - | |

| 60.70 | 273.05 | 90.33 | 13.84 | - | - | - | - | PSB | PSB | PSB | |

| 65.70 | 273.05 | 97.77 | 15.11 | - | - | - | - | PSB | PSB | PSB | |

| 73.20 | 273.05 | 108.94 | 17.07 | - | - | - | - | P | - | - | |

| 79.20 | 273.05 | 117.87 | 18.64 | - | - | - | - | P | - | - | |

| 85.30 | 273.05 | 126.94 | 20.24 | - | - | - | - | P | - | - | |

| 11-3/4 | 42.00 | 298.45 | 62.50 | 8.46 | - | - | - | - | - | - | - |

| 47.00 | 298.45 | 69.95 | 9.53 | PSB | PSB | - | - | - | - | - | |

| 54.00 | 298.45 | 80.36 | 11.05 | PSB | PSB | - | - | - | - | - | |

| 60.00 | 298.45 | 89.29 | 12.42 | PSB | PSB | PSB | PSB | PSB | PSB | PSB | |

| 65.00 | 298.45 | 96.73 | 13.56 | - | - | P | P | P | P | P | |

| 71.00 | 298.45 | 105.66 | 14.78 | - | - | P | P | P | P | P | |

| 13-3/8 | 48.00 | 339.72 | 71.43 | 8.38 | - | - | - | - | - | - | - |

| 54.50 | 339.72 | 81.11 | 9.65 | PSB | PSB | - | - | - | - | - | |

| 61.00 | 339.72 | 90.78 | 10.92 | PSB | PSB | - | - | - | - | - | |

| 68.00 | 339.72 | 101.20 | 12.19 | PSB | PSB | PSB | PSB | PSB | PSB | - | |

| 72.00 | 339.72 | 107.15 | 13.06 | - | - | PSB | PSB | PSB | PSB | PSB | |

| 16 | 65.00 | 406.40 | 96.73 | 9.53 | - | - | - | - | - | - | - |

| 75.00 | 406.40 | 111.62 | 11.13 | PSB | PSB | - | - | - | - | - | |

| 84.00 | 406.40 | 125.01 | 12.57 | PSB | PSB | - | - | - | - | - | |

| 109.00 | 406.40 | 162.21 | 16.66 | P | - | P | P | - | P | P | |

| 18-5/8 | 87.50 | 473.08 | 130.22 | 11.05 | PSB | PSB | - | - | - | - | - |

| 20 | 94.00 | 508.00 | 139.89 | 11.13 | PSLB | PSLB | - | - | - | - | - |

| 106.50 | 508.00 | 158.49 | 12.70 | PSLB | PSLB | - | - | - | - | - | |

| 133.00 | 508.00 | 197.93 | 16.13 | PSLB | - | - | - | - | - | - | |

* P - plain end, S - short round thread, B - buttress, L - long round thread.

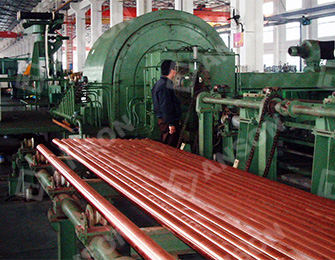

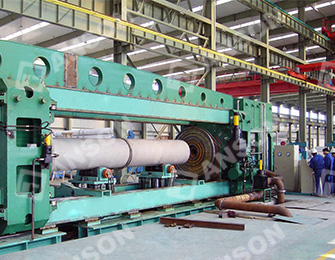

Please follow us to know how the casing pipes produced as below details:

|

|

| Workshop | Raw materials |

|

|

| Ingot heating | Hot rolling |

|

|

| Plug mill | Cooling |

|

|

| Cutting | Threading |

|

|

| Painting | Hydraulic pressure |

Our mill has built a complete and effective quality system under ISO9001. With the approval of American Petroleum institute, our mill is awarded with API5 CT certificate.

Casing pipes we offered conform to international standard API/ EN/ ASTM, and can pass any third party’s inspection like SGS, BV. In order to assure compliance to applicability terms, we inspect the pipes through a set of proven tests & inspections including: dimensional inspections, tensile test, corrosion test, non-destructive test, hydrostatic test, x-ray test.

|

|

|

|