As we all know, pipelines play an indispensible part in oil and gas transporting market. Thus, it is crucial to ensure the integrity and good performance of pipelines in real practice. In addition to strict manufacturing process, thorough and professional inspection is also a decisive factor in pipeline performance. Now let’s get to know some key inspection methods.

Nondestructive Testing, shorted for NDT, is a widely-used method in pipeline inspection. It is a process of testing, inspecting and evaluating the quality and characteristics of the material without damaging the pipeline itself or affecting the later regular work of the pipe. In other words, after NDT testing, the part can still be put into practical use. NDT utilizes the changes in heat, sound and magnets caused by abnormal inner structure or flaws to inspect the internal and external defects of the material.

The common inspection methods of NDT are visual testing (VT), ultrasonic testing (UT), radiographic testing (RT), hydrostatic testing. Anson International co, ltd uses ultrasonic testing (UT) and hydrostatic testing to inspect its line pipes.

Hydrostatic test is an inspection method to reduce the risk of flaws in the pipe that might threaten its ability to withstand the maximum operating pressure. Hydrostatic testing inspects the integrity of pipelines by filling in the pipe with a non-compressible liquid (often water, dyed) to increase the pressure level above the normal pressure to see if there is any defect exists. It can either carried out on pipes prior to being put into service or on existing pipes that are already in service.

In order to carry out hydrostatic testing, the following rules should be strictly stuck to:

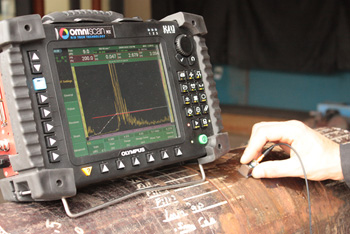

Ultrasonic testing, also known as UT, enjoyed wide application in the flaw detection and quality control of metallurgy and manufacturing industry. It is able to precisely detect, inspect and diagnose the flaws in the material.

In an ultrasonic test, the ultrasonic transducer connected to a diagnostic machine is put on the pipeline to be inspected. High frequency sound waves can directly travel through the metallic material. If the sound waves hit a defect, normally with a different acoustic obstruction, some of the waves will reflect back to the sending unit and inspectors can see the results in the form of signals on the visual display. By analyzing the reflection, inspectors can locate and test the crack or other hidden defects.

Ultrasonic testing bears a number of benefits in the application of pipeline inspection:

In contrast to NDT, there are some destructive inspection methods. They are always carried out on samples of the material instead of on material itself. Destructive inspecting methods are normally used to test the physical properties of the material, such as tensile strength, yield strength, hardness and so on. Suppliers can choose the most suitable inspection methods according to your practical needs.