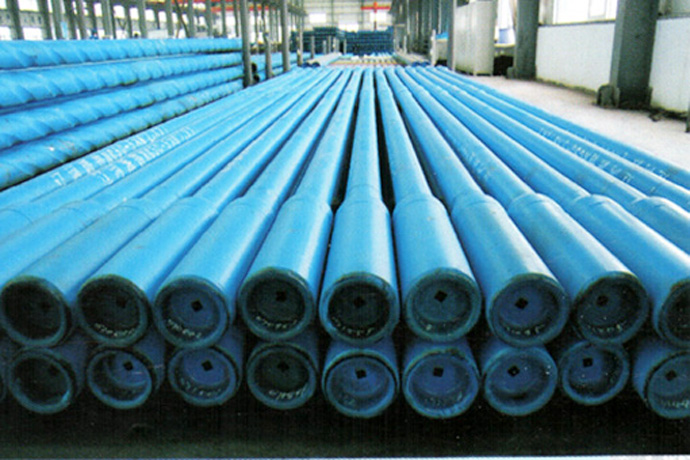

Heavy-weight drill pipe is made from AISI 4145H steel, after all the heat treatment of materials, all physical properties comply with recent provisions of API specification 7. Integral heavy weight drill pipe is a common transition between the drill pipe and drill collars of the drill, which can effectively alleviate the drill collars and transition in the combined stress concentration provides drilling, and can effectively reduce the drill and the wear rate of the connection area and diameter of the borehole. Drill pipe in central part of the thickened, welding joints and thickened in the middle part of the appearance of cemented carbide wear, can effectively protect the pipe from wear and tear. In a soft case of geological formations, heavy weight drill pipe can replace the drill collar to solve a series of problems occurred in vertical drilling.

Most commonly, heavy-weight drill pipe is used as a transition between the normal drill pipe and the heavier drill collars. Standard pipe can’t bear drill collars of vibration and intense pressure at the bottom, so heavy-weight drill pipe in this part of the drill string to withstand harsh conditions. Heavy-weight drill pipe looks very similar to the normal drill pipe, but it's processing in the form of more delicate than the drill collar has more flexibility at the same time.

In some applications, heavy-weight drill pipe may also be used in place of the drill collars。It is used most commonly in directional drilling. Because it bends easily, it simplifies directional control and minimizes connection fatigue problems common to high-angle or horizontal drilling.

Between the drill collar and ordinary drill pipe connection 15~30 roots weighted drill pipe can prevent the drill pipe from fatigue damage.

After directional well drilling column connected to the heavy weight drill pipe, the drill collar and heavy-weight drill pipe is not close to the wall, so as to reduce the possibility of mud cake sticking and breakout torque is reduced. Meanwhile the drill in provided tension will not exceed the well too much weight. In addition, it is better to control the angle and azimuth angle of the well and reduce the number of directional work, so as to shorten the construction period of directional well.

In the process of drilling, the failure of drill pipe in any part will cause serious consequences, and even the well abandoned. With the continuous depletion of shallow resources, the safety and reliability of drill pipe has become a very prominent problem in the future.

Drill pipe failure is generally manifested as the main body fracture and puncture, failure of drill pipe thread, etc. The reason is generally caused by the following factors: drilling drill pipe in basic mechanics conditions, drilling tool combination and drilling technology, caliper rule, eccentric wear, thread sealing grease, drilling fluid, drill pipe structure and material, formation factor, well within the corrosive medium, the result of the interaction of the above factors lead to drill pipe failure.

In summary, the failure of drill pipe is various, and the failure of drill pipe is the result of the combined action of each factor. In terms of each well, We should according to the drillpipe failure analysis, extract the main influence factors and take corresponding measures.