OCTG casing is a steel pipe supporting oil and gas well wall, which ensures the normal operation of the entire well after the drilling process carried out. Different from tubing and drill pipe, casing can not be repeated use and belongs to a one-time consumption of materials. Therefore, the consumption of the casing pipe accounted for more than 70% of all. According to the situation of use, casing can be divided into: tube, surface casing, technical casing and oil layer casing.

Mainly used for drilling in the desert and ocean, to separate water and sand and ensure the drilling smoothly. The main specifications of this casing is: ∮762mm(30in)×25.4mm, ∮762mm(30in)×19.06mm.

In the first drilling, it is used to drill the soft ground until the bedrock layer. In order to seal this part of the formation without collapse, general use surface casing to seal. The main specifications of surface casing is: 508mm(20in), 406.4mm(16in), 339.73mm(13-3/8in), 273.05mm(10-3/4in), 244.48mm(9-5/8in). The depth of the surface casing depends on the depth of the soft ground, generally 80~1500m. Its external pressure and internal pressure is not large, generally using K55 steel grade or N80 steel grade.

Because some wells are deep and complex and the depth of the well is several kilometers, this kind of deep well needs to use the technical casing. Its mechanical properties and sealing performance requirements are very high, the steel grade is also higher. In addition to K55, most of it use N80 and P110 steel grade and some deep wells also use Q125. The main specifications of technical casing is: 339.73mm(13-3/8in), 273.05mm(10-3/4in), 244.48mm(9-5/8in), 219.08mm(8-5/8in), 193.68mm(7- 5/8in), 177.8mm(7in).

When drilling to the oil layer, the oil layer casing is used to seal hydrocarbon reservoir and the internal of it is tubing. The oil layer casing is the deepest in the different casing and the mechanical properties and sealing performance requirements of it are the highest. The main specifications of oil layer casing is: 177.8mm(7in), 168.28mm(6-5/8in), 139.7mm(5-1/2in), 127mm(5in), 114.3mm(4-1/2in).

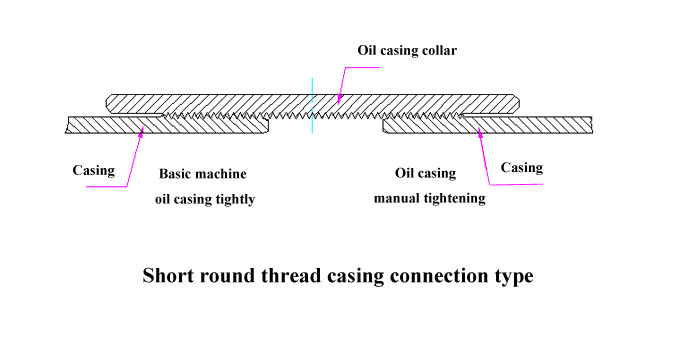

The short round thread casing is one of the product types in the petroleum casing pipe. Short round thread casing features: 1. Improve resistance caused by abrasion when the thread in the screw. 2. When tightening screw, tooth gap provides a reasonable gap for foreign particles and dirt. 3.The arc tooth top is not sensitive for local scratch or dent damage.

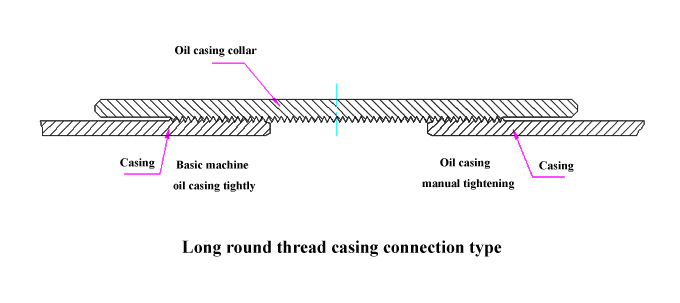

Long round thread casing is widely used as a buckle-shaped of oil casing. Due to the thread shape at both ends of the pipe body is like long round, so it’s called long round thread casing. Long round thread has the advantages of easy processing, good sealing performance, strong connection strength and cheap, so it’s widely used in the casing connection.

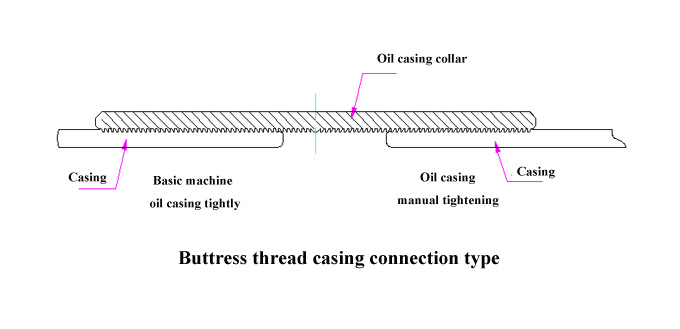

Buttress thread casing have the name because the thread form is like partial trapezoidal and this thread is widely used in all the thread. The packing of the buttress thread casing is tied up with the steel wire or the steel band. The advantages of this thread improve axial tension and axial compression load and the leakage resistance is also provided.