Pipe end machining is that the process of pipe thread, sizing, thickening, strengthen the heat treatment, chamfering and other processes are carried out on the end of pipe. Each process is quite important for carrying out the pipe end machining, let’s look at all the processes together.

Pipe end thickening is mainly used for the oil pipe and geological tube. Since the pipe wall will be thinned after the end of processing, the part of threaded connection has become the weak link of the whole pipe body. In order to improve the strength of the connecting part of the thread, the method of pipe end thickening is adopted to increase the wall thickness of the pipe end. There are 3 forms of pipe end upsetting, internal upsetting, external upsetting, internal and external upset.

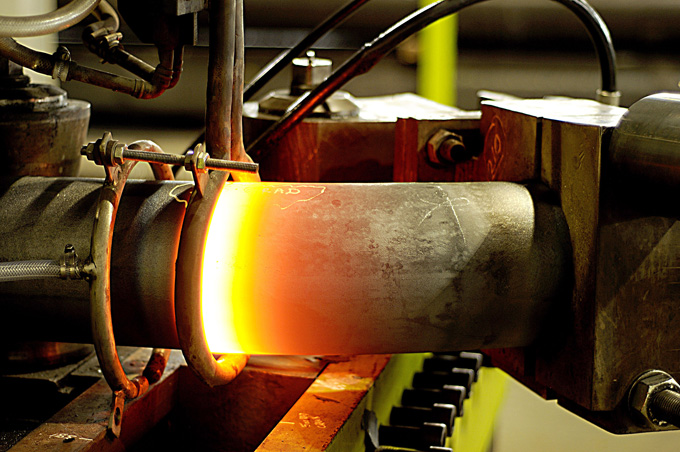

The process of pipe end thickening is: pipe end heated→thickened→cooled→checked. According to the size of the thickened tube, the thickness of the form and the amount of thickening of the compression, the number of heating and thickening is not the same, there is one heating one thickening, or two thickening one heating. In order to eliminate the phenomenon of uneven performance of the thickened end and the pipe body caused by the thickening, the steel pipe usually does integral heat treatment after thickening.

The purpose of pipe end sizing is to reduce the degree of ellipse of steel tube, and ensure the dimensional accuracy of steel tube after machining. It is mainly used for oil casing. Pipe end sizing adopts cold deformation process. There are two common methods of sizing, punch diameter and punch diameter + sizing compression ring. To a large extent, the effect of reducing the degree of elliptical steel tube depends on the degree of uniformity of wall thickness when punch diameter. Hot rolled tube with serious wall thickness, such as steel pipe rolling of the rotary forging mill, surface quality of pipe end will be deteriorated after punching diameter. Therefore, in order to eliminate the effect of wall thickness of the uneven and reduce the degree of ovality, punch diameter + sizing compression ring should be taken. Due to the cold sizing and pipe end not only generate elastic deformation but also a small amount of plastic deformation, at the same time it may appear inside and outside surface scratch and produce slight stress corrosion phenomenon. So we should try to improve the dimensional accuracy of steel tube rolling, avoiding the use of pipe end sizing method.

The length of a single tube length is usually less than 14m, but for some steel pipe, the length required often greatly exceeds the length of this. Such as in geological drilling and oil drilling, drilling depth is usually above 1000 meters and the deepest can reach 7000; Used for transporting oil, gas, water, alkali, mineral conveying pipe is up to several kilometers or even hundreds of kilometers. Therefore, it is necessary to connect pipe with coupling in the two ends of the steel pipe threading. Threaded connection requires high connection strength, good air tightness, in order to prevent fracture of steel pipe and leakage of conveying articles. A variety of forms of thread have developed in the world to meet the needs of a variety of purposes. Mainly adopt the following three kinds:

Dome triangular thread, which is characterized by simple thread processing, but because of uneven force and deformation of the screw thread, the connection strength is low. Poor sealing performance is caused by only on the side of the thread sealing.

Buttress Thread, which has the characteristics of high thread precision, high processing requirement and high connection strength. Sealing performance is relatively high rely on the side and the top of the screw seal.

Direct connection type, whose characteristic is that the pipe ends need to be thicker, one end of external screw thread and the other end of internal screw thread, so the processing is more difficult. However, due to the high precision of screw thread, the connection strength performs well.

Through heat treatment, the strength of the pipe end is higher than that of the pipe body strength. The process of pipe end heat treatment includes the tube end heating, quenching and tempering. Some points to remember: