API Standards for Oil Tubing

What is API?

API, referring to “American Petroleum Institute”, founded in 1919, is the largest trade association for oil and gas industry in America, and one of the world’s most successful chambers of commerce that contributes to the standardization of oil production. API specification is widely used all over the world due to its safety, versatility and advancement. The main function of API is to define and draft standards to qualify the oil and petrol industry, ensuring the safety and reliability of the industrial equipment. Therefore, the equipment with API specification is not only considered as highly qualified but leading positioned in the field as well.

Types of API Tubing

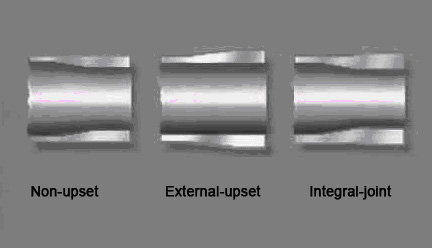

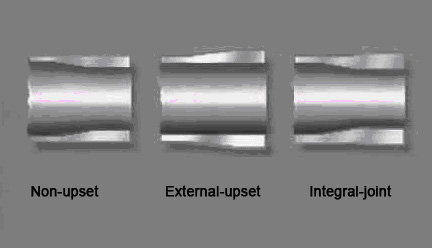

The tube is the devise used to transport oil or natural gas from the hydrocarbon reservoir to the earth surface. Tubes mainly include three different kinds, namely non-upset tubing (NU), external upset tubing (EU) and integral joint tubing (IJ). NU refers to the tube whose ends are threaded and coupling directly without being thickened. EU means both ends of the tube are thickened, threaded and then coupling. IJ refers to the tube whose ends are connected without coupling, one end being threaded through internal thickened and the other through external thickened.

API Tube Grades

API divides tubing grades into three groups. Group 1 is for all tubing in grades H40, J55, and N80. Group 2 is for restricted-yield tubing grades L80, C90, and T95. Group 3 is for high-strength tubing in seamless grade P110. The API grade letter designation was arbitrarily selected to provide a unique name for various steels. Numbers in the grade designation indicate the minimum yield strength of the steel in thousand psi. API defines the yield strength as the tensile stress required to produce a specific total elongation per unit length on a standard test specimen.

Grade H40 is generally not used in tubing sizes due to the relatively low yield strength. J55, commonly used grade for most wells, has been the "standard" grade for tubing in most relatively shallow (< 9,000 ft) and low-pressure (< 4,000 psi) wells on land. N80, a relatively old grade with open chemical requirements, is susceptible to H2S and acceptable for sweet oil and gas wells in design conditions. L80 is a restricted yield-tubing grade that is available in Type 1, 9Cr, or 13Cr. L80Type 1 is less expensive, but more subjects to weight-loss corrosion, commonly used in oil and gas fields. Despite the popularity for CO2-and mild H2S-contaminated wells in the past, Type 9Cr has largely been supplanted by Type 13Cr. L80 13Cr tubing has become popular for its good CO2-induced weight-loss corrosion resistance properties. C90 is relatively new with two different chemical requirements: Type 1 and Type 2. Only Type 1 is recommended for use in sour service. T95 is a high-strength tubular grade with different chemical requirements: Type 1 and Type 2. Only Type 1 is recommended for sour service. P110, the high-strength tubing, is normally used in deep sweet oil and gas wells under high pressure. This grade is sensitive to SSC failures unless the temperatures are relatively high (> 175°F).

API Tubes are supposed to bear the pressure during the extraction period, which means it should be of great pressure resistance and proper malleability. Besides, it ought to be sized to perfectly satisfy the expected rates of oil and gas products, neither too big nor too small. API 5CT and 5B make specific requirements to the production of tubes, such as tensile strength, yield strength, elongation and hardness, etc.

Anson API Tube

Henan Anson Steel Co., Ltd is devoted to supplying

OCTG products with reliable quality and competitive price. Boasting years of experience, we possess profound knowledge, professional work team, and most importantly, excellent products catering to customers’ needs, even beyond their expectations. The tubes manufactured in our company are completely certified by the API 5CT, with an outside diameter ranging from 1.660* to 4 1/2* (42.16mm to 114.3mm) and wall thickness from 2.3 PPF to 26.10 PPF (3.57mm to 9.52mm). Besides, they are made to withstand the pressure generated from the extraction process, owning suitable tensile and yield strength and pressure resistance.

With API certified, we promise to provide the top quality tubes, sincerely looking forward to offering you the best products, as well as the perfect service.